Shivank Conveyor Belts also supplies a wide range of Special Conveyor Belts from Forech, designed for customized applications across industries. These include Heat-Resistant Belts, Oil-Resistant Belts, Flame-Resistant Belts, and Hygienic Food-Grade Belts. Each belt is engineered to meet specific operational demands—whether it’s withstanding extreme temperatures, resisting abrasion, or maintaining hygiene in food processing. With Forech’s advanced technology and Shivank’s trusted distribution, Special Conveyor Belts provide reliable performance in the most demanding environments.

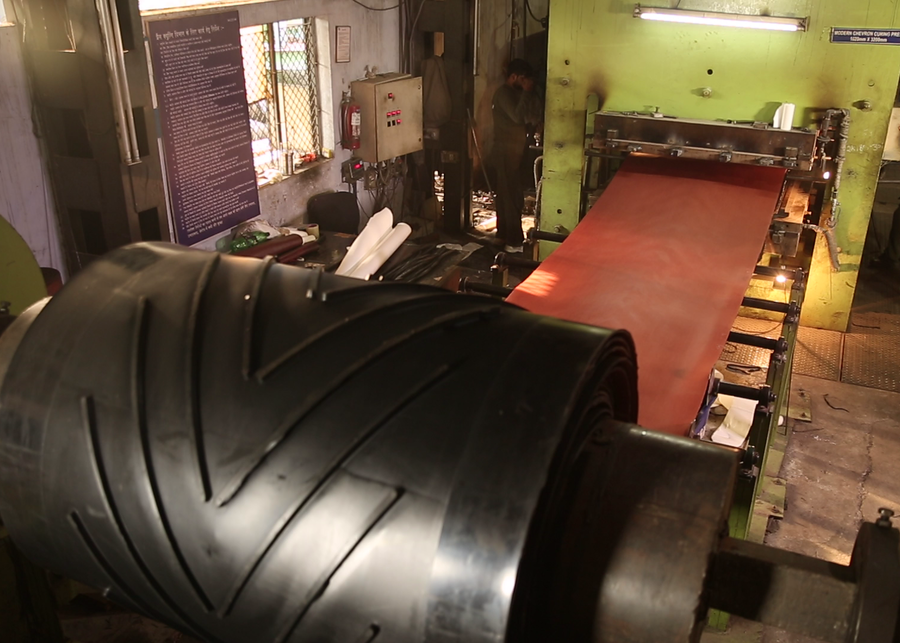

Chevron Conveyor Belts

With smooth surface conveyor belts, the maximum conveying angle of inclination is approximately 20° depending on the material. Using chevron cleated belts makes steeper angles of inclinations up to 40° possible, which allows for higher lift in lesser space.

Chevron conveyor belts have rubber cleats that are integrally vulcanized with the top cover of the belt. These profiles are made with highly abrasion resistant rubber types and are offered in softer compounds (45 to 50 Shore hardness) as also 60 shore materials. The profiles are shaped in such a manner that there is no need for special idlers and these can be run on conventional conveyors. The pitch between two cleats ensures a smooth ride over return idlers.

Characteristics

Belt Width

Depending upon the profile, chevron belts are available in widths from 600 mm to 1800 mm.

Edges

Chevron Belts are normally supplied with cut edges. However, Belts with moulded edges can also be supplied.

Patterned Conveyor Belt

Wavy-top conveyor belts, herringbones conveyor belts, and a host of other options are available in open ends or built endless. Multi-V constructions with 1/4 inch (6 mm) height are also available.

Special Profile Weigh Conveyor Belt

Forech manufactures special profile weigh feeder belts for use in thermal power plants and cement factories. These are highly caliberated seamless belts with side profiles and centre guides.

Custom Belts

Forech has the expertise to design a new chevron profiled design to meet your needs with it’s experience in mould manufacturing and product designing.

Sidewall Conveyor Belts

Forech’s unique Sidewall Belts allow end users to carry bulk materials at high inclines and angles up to 90 degrees. This allows material to be carried where space requirements are critical, and increases overall belt efficiency and throughput.

Applications

Forech’s sidewall belts can be used in multiple industries to successfully meet space and efficiency constraints. These industries include:

- Coal and Wood Chips Fired Power Stations

- Underground Mining (coal and ore)

- Ship Loading and Unloading, Ship to Ship loading

- Sand preparation in foundry plants

- Slope conveying in open-pit mining

- Steep angle carrying in road construction machines

Benefits

One of the key advantages of Forech’s sidewall belting is the use of cross-rigid base belts. These specially tailored belts can be deflected from the horizontal to a perpendicular incline and back again without any bowing or sagging in the belt.

This is achieved through custom-made fabric constructions, a special belt composition and our in-house production procedure. This ensures that our sidewall belts have a long life and can withstand operating pressures at high inclines.

Characteristics

Choosing Between Cold and Hot Vulcanised Belts

As sidewall belts usually operate in enclosed conditions, the usual temperature ratings applied to flat rubber conveyor belts cannot be applied. Increased temperature exposure over the life of the belt results in accelerated ageing and a reduction in belt elasticity which adversely effects the belt life.

The effective belt operating temperature therefore determines operating life of the belt.

If the operating temperature is consistently above 70° C, as in the case of heat resistant applications, Forech recommends, use of Hot Vulcanised high angle belts. This is because at high operating temperatures, the cold bonding adhesives used for both the cleats, sidewalls and the belt-splice start to break down. To ensure trouble free service in such applications Forech offers sidewall belts with the cleats and the sidewall in heat resistant quality which are fixed on the base belt with hot vulcanisation.

The operating temperatures listed above for standard quality can be increased by 30°C if a Heat Resistant belt is used.